Equipment, especially electrical devices, may only be used in hazardous environments with explosive atmospheres if they have been tested and approved for their explosion protection properties by a recognized and accredited testing authority. This requirement underlines the shared goal of operators and manufacturers of explosion-proof equipment to provide the safest possible working environment for personnel of industrial facilities. Needless to say, for manufacturers of explosion-proof equipment such as INDUSTRONIC it is also an invaluable asset and door opener for global business being able to provide product certifications proving compliance to related national and international standards.

An international widely accepted certification system for equipment for use in explosive atmospheres is the IECEx, developed and observed by its patronage organization: the International Electrotechnical Commission (IEC). The IEC is striving for the worldwide harmonization of regulations and standards and promoting the mutual recognition of product assessments and test reports. The IECEx certification does not replace the still important local certifications of various markets such as the ATEX directive for the European Union or the compliance to the National Electric Code (NEC) through a Nationally Recognized Testing Laboratory (NRTL) in the United States. One advantage of having an IECEx certification is an accelerated local certification, given that the inspecting laboratory is accredited for both the IECEx and the local codes & standards.

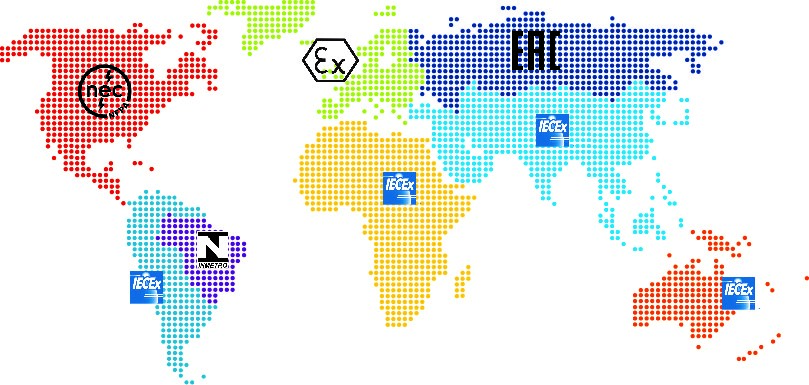

World map showing the various prevalent EX certification systems and bodies.

One of our recent products which had been successfully assessed for IECEx compliance, after undergoing its ATEX EU-Type-Examination first, is the digital explosion-proof intercom stations of the series DX 7×5 and DXE 7×5. INDUSTRONIC had to provide product samples to an approved IECEx Certification Body (ExCB) which thoroughly inspected the DX(E) 7×5 resulting in the issuance of the Product Assessment and Test Report (IECEx ExTR). But not only the product itself is under scrutiny of the IECEx specifications, the manufacturing facilities and their quality assurance scheme are also inspected during this process and documented in the Quality Assessment Report (IECEx QAR). Only if both inspections are successful the official Certificate of Conformity (IECEx CoC) is granted.

We, as a manufacturer of PAGA and Intercom system for the industry, are proud that our products reach the high standards of the IECEx and their local counterparts and look forward to continuously providing our clients with solutions compliant to their local safety requirements.

You can follow the link below to the IECEx certificate and the quality report of our latest DX(E) product line: